Innovative Recycling Methods for Sustainable Hydrogen Electrolysers

Key Ideas

- Researchers at Helmholtz Institute Freiberg have developed innovative flotation processes to recover critical metals like platinum and nickel from hydrogen electrolysers, supporting sustainability.

- The H2Giga project in Germany, funded by the BMBF, focuses on investigating the longevity and recyclability of hydrogen electrolysers as part of the national hydrogen strategy.

- By recovering up to 90% of functional materials using ultra-fine particle separation and agglomeration flotation, the researchers aim to contribute to the economic and sustainable operation of hydrogen electrolysis.

- The project includes developing a scalable recycling process, conducting technology assessments, and emphasizing the importance of recycling for sustainability and cost efficiency in the hydrogen economy.

Hydrogen plays a crucial role in the energy transition as a clean energy source to reduce CO2 emissions. The production of hydrogen through water electrolysis using renewable energy sources like wind and solar power is gaining prominence. In Germany, the national hydrogen strategy aims to utilize 95 to 135 terawatt hours of hydrogen by 2030. The focus on green hydrogen extends to various sectors such as industry, transportation, and energy storage, making it essential for a sustainable energy future.

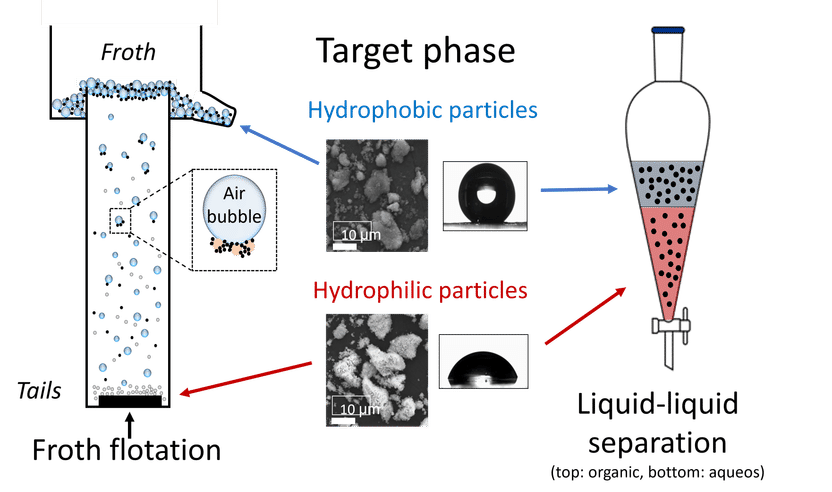

Researchers at the Helmholtz Institute Freiberg have been working on the recycling of critical functional materials in hydrogen electrolysers. The project, part of the H2Giga initiative funded by the German Federal Ministry of Education and Research (BMBF), aims to ensure the longevity and recyclability of electrolysers. Through innovative flotation processes and liquid-liquid particle separation techniques, up to 90% of platinum group metals, rare earths, and nickel can be recovered and reintroduced into the material cycle.

The ReNaRe project under H2Giga specifically focuses on the end-of-life phase of electrolysers, emphasizing the importance of returning critical metals to the material cycle. Ultra-fine particle separation techniques are employed to recover cathode and anode materials, which are present in extremely small sizes. By using sustainable solvent-water circulation systems and agglomeration flotation, the researchers have made significant progress in efficient material recovery.

The project also includes the development of a scalable recycling process that aligns with current and future technological advancements. Furthermore, technology assessments like life cycle analyses and techno-economic analyses are being conducted to quantify the sustainability and cost benefits of recycling in the hydrogen economy. The collaborative efforts aim to promote the economic and sustainable operation of hydrogen electrolysis through efficient material recovery and recycling.

Topics

Production

Technology

Innovation

Sustainability

Energy Transition

Research

Hydrogen Economy

Recycling

Metal Recovery

Latest News