Innovative Method: Transforming Plastic Waste into Hydrogen for Clean Energy

Key Ideas

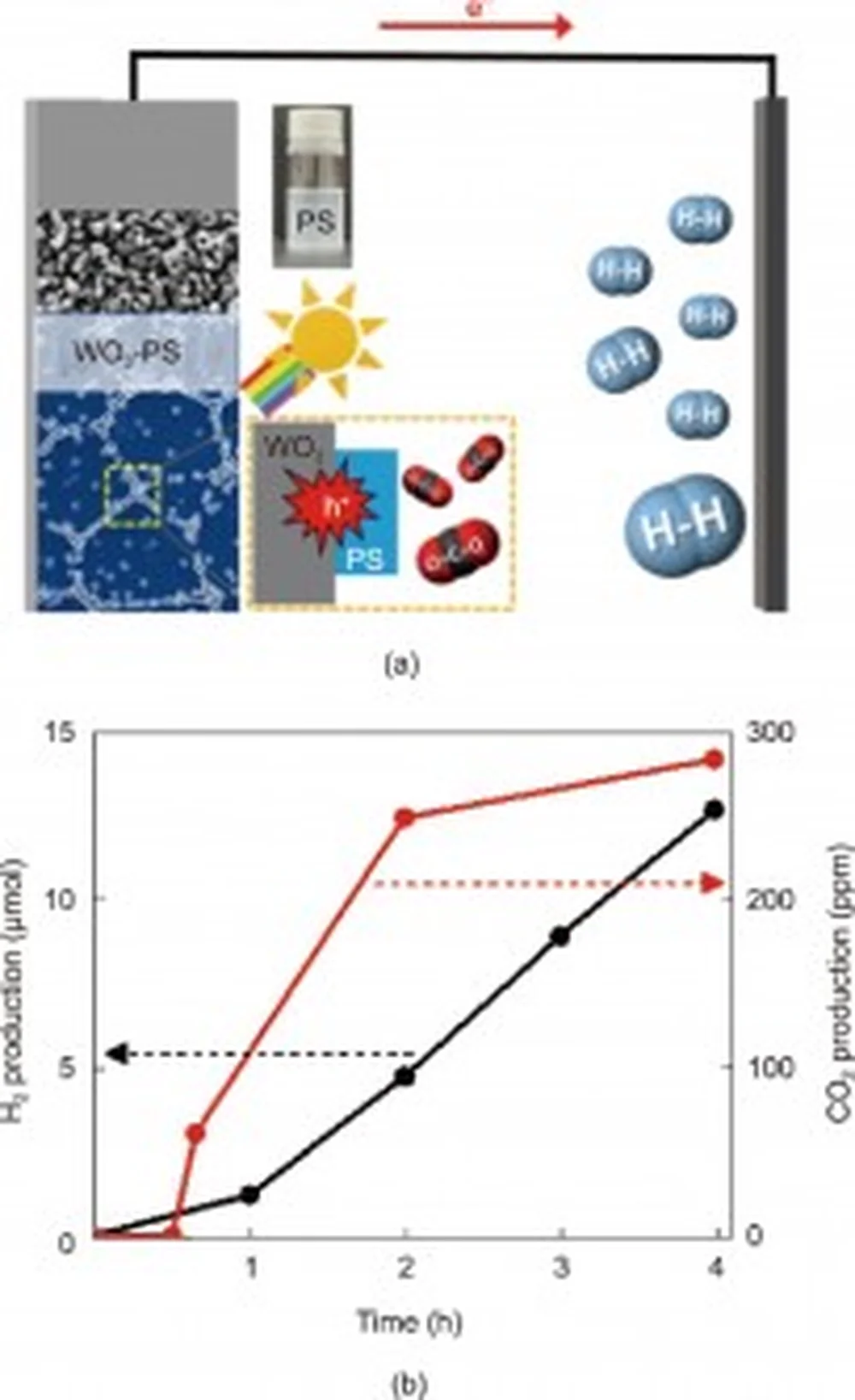

- Researchers at KIST developed a method to convert plastic waste into hydrogen for clean energy production through a porous tungsten oxide photoanode.

- The produced hydrogen can be utilized in fuel cells, store excess energy, and potentially offset fossil fuel use to neutralize CO2 emissions.

- This innovative approach not only provides a cleaner alternative to incineration but also has the potential to be carbon-neutral.

- Another research at the University of Edinburgh involves reprogramming bacteria to convert plastic into paracetamol, reducing carbon emissions from traditional production methods.

Researchers at the Korea Institute of Science and Technology (KIST) have devised a groundbreaking method to transform plastic waste into hydrogen, a clean energy source. By utilizing a porous tungsten oxide (WO3) photoanode, they interact with polystyrene (PS) plastic commonly found in various products. The process involves dissolving PS in chloroform and depositing it onto the WO3 photoanode, which then utilizes light energy to convert PS into CO2 and generate hydrogen gas. The produced hydrogen not only serves as a sustainable energy source but can also aid in storing excess energy and potentially neutralizing CO2 emissions. Additionally, researchers at the University of Michigan have developed a method to utilize carbon dioxide for generating clean energy by converting it into metal oxalates. This innovative approach presents a cleaner alternative to incinerating plastic, thus reducing greenhouse gas emissions and toxic chemicals. The method's potential for becoming carbon-neutral is highlighted through the utilization of hydrogen for clean energy production, offsetting fossil fuel use. Furthermore, a separate research initiative at the University of Edinburgh involves genetically reprogramming E. coli bacteria to convert plastic waste into paracetamol, offering a sustainable alternative with minimal carbon emissions compared to traditional production methods. These innovative approaches showcase the potential for turning plastic waste into valuable resources while promoting sustainability and reducing environmental impact.