H2SITE Receives EIC Accelerator Funding for Groundbreaking Ammonia Cracking Technology

Key Ideas

- H2SITE has secured EIC Accelerator funding to deploy a cutting-edge ammonia cracking unit capable of producing 1 ton of high-purity hydrogen per day using their proprietary membrane reactor technology.

- The technology offers advantages such as the lowest Levelized Cost of Hydrogen from ammonia, reduced energy consumption, high-purity hydrogen output suitable for various applications, and a compact modular design for decentralized production.

- The project aims to validate H2SITE's membrane reactor approach at an industrial scale, contributing to the advancement of decarbonization efforts in hard-to-abate sectors and enabling competitive hydrogen supply chains, especially in the maritime industry.

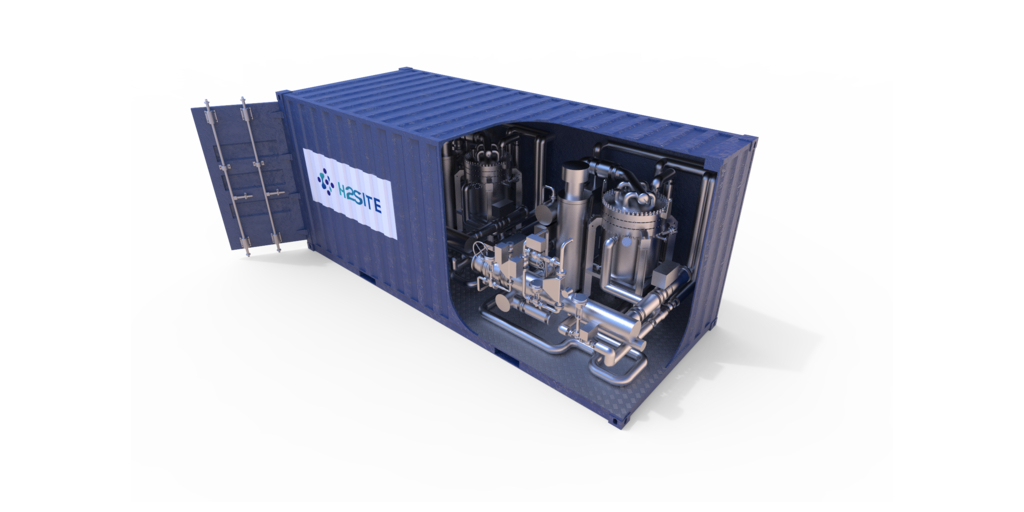

H2SITE, a technology company based in Bilbao, Spain, has been granted the EIC Accelerator program for their innovative project focused on deploying a groundbreaking ammonia cracking unit capable of producing 1 ton of high-purity hydrogen per day. This project is based on H2SITE's proprietary palladium-based membrane reactor technology, enabling efficient catalytic decomposition of ammonia and selective hydrogen separation in a single unit. The technology offers significant advantages over traditional methods, including a lower Levelized Cost of Hydrogen (LCOH), reduced energy consumption, high-purity hydrogen output suitable for fuel cells and industrial applications, and a compact modular design for decentralized production near demand centers.

The ammonia cracking system will act as a demonstration plant to validate the commercial viability of H2SITE's integrated membrane reactor approach at an industrially relevant scale, aiming to contribute to the decarbonization of challenging sectors. Andres Galnares, the CEO of H2SITE, emphasized the importance of this project in advancing the commercialization of their technology for various industrial sectors, energy hubs, and maritime applications. As the hydrogen economy expands, efficient solutions for transporting low-carbon hydrogen are crucial. Ammonia is considered a promising hydrogen carrier due to its energy density and existing infrastructure. With over 20 million tons of ammonia transported by ship annually, advancements in technologies like H2SITE's integrated membrane reactor are key to enabling competitive large-scale hydrogen supply chains, especially in the maritime industry. H2SITE, established in 2020, focuses on on-site production and separation of high-purity hydrogen using palladium-alloy membrane reactor technology, converting feedstocks like ammonia and methanol into hydrogen efficiently. By decentralizing hydrogen production and offering innovative ammonia cracking solutions, H2SITE addresses challenges in cost-effective hydrogen transportation and storage, thus reducing associated costs and emissions.

Topics

Europe

Technology

Innovation

Energy Efficiency

Industrial Applications

Carbon Reduction

Energy Sector

Decarbonization

Maritime Industry

Latest News