Ineos Hull Site Transformation: Leading the Charge in Clean Hydrogen Production

Key Ideas

- Ineos completes a £30m upgrade in Hull to convert operations to clean hydrogen, reducing CO2 emissions by 75%.

- Blue hydrogen, a co-product sourced from BP, is used in essential chemical production like acetic acid and ethyl acetate.

- CEO David Brooks highlights the company's commitment to reducing carbon costs and competing in global markets.

- Ineos invests in the transformation now, emphasizing proactive measures rather than waiting for future targets.

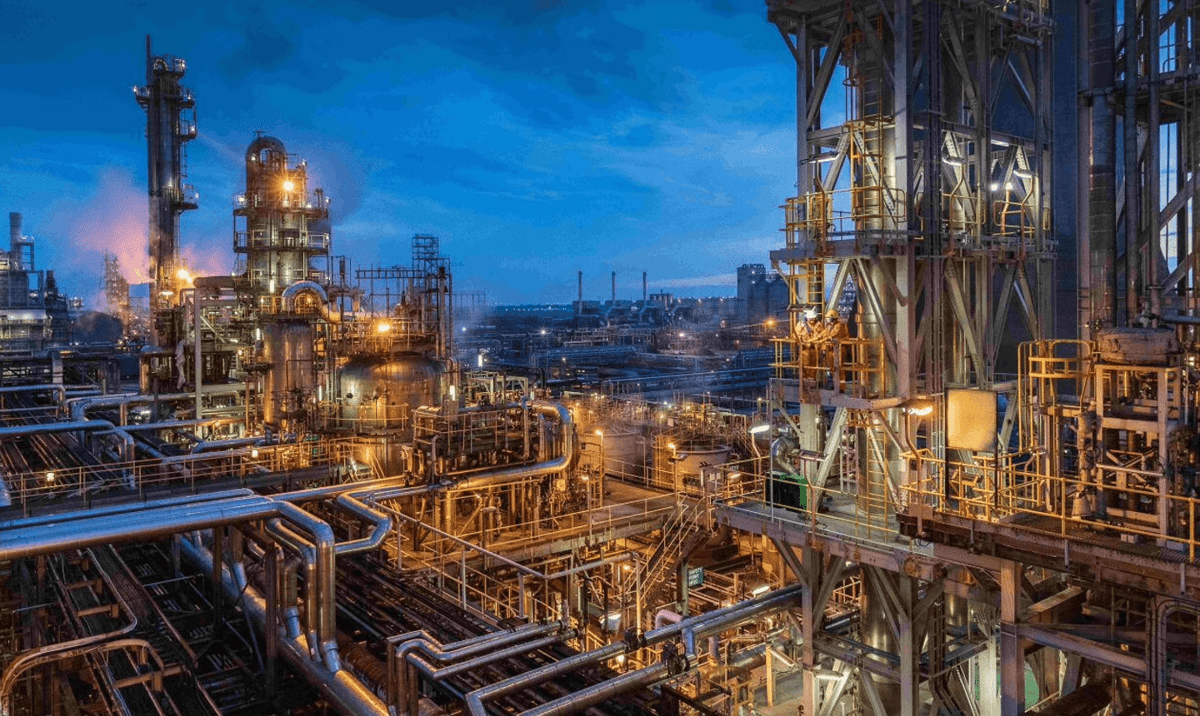

Ineos, a UK-based chemicals maker, has recently completed a £30m upgrade at its Hull manufacturing site, marking a significant shift towards clean hydrogen production. This transformation has led to a remarkable 75% reduction in CO2 emissions, equivalent to removing 160,000 petrol cars from the road. The use of blue hydrogen, acquired as a co-product of existing processes at the Hull site, plays a vital role in producing essential chemicals like acetic acid and ethyl acetate, crucial for pharmaceutical, water treatment, and food preservation industries. CEO David Brooks underlines the company's proactive stance in tackling energy and carbon challenges in the competitive global market landscape. Despite regulatory disputes with the UK Environment Agency over emissions trading scheme allowances, Ineos remains steadfast in its commitment to sustainability and operational efficiency. This investment not only showcases Ineos' dedication to immediate action but also sets a pioneering example in the industry's transition towards cleaner energy sources.