Innovative Approaches for Sustainable Steel Production

Key Ideas

- Utilizing biomass in the ferrous metallurgical industry shows potential for sustainable steel production.

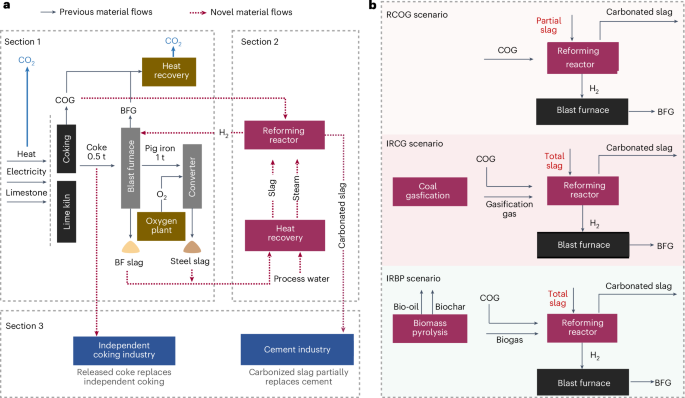

- New technologies like formate production from industrial off-gases and carbon-containing pellets aim to reduce carbon emissions.

- Research on waste heat recovery and the use of steelmaking slag for energy recovery are key focus areas for sustainability.

- Hydrogen injection and direct reduced iron usage in blast furnaces are simulated for reducing carbon dioxide emissions in steel production.

The steel industry faces challenges in reducing its environmental impact, particularly regarding carbon emissions. Various studies and research are being conducted worldwide to find innovative solutions for sustainable steel production. Biomass utilization in the ferrous metallurgical industry has shown promise, offering a renewable alternative to traditional energy sources. Technologies like formate production from industrial off-gases and the use of carbon-containing pellets aim to reduce carbon emissions significantly.

Another area of focus is waste heat recovery, where researchers are exploring ways to recover energy from hot slags, contributing to both energy efficiency and emission reduction. Additionally, the utilization of steelmaking slag for energy recovery is being studied for its potential in reducing environmental impact.

Furthermore, simulations involving hydrogen injection into blast furnaces and the use of direct reduced iron are being researched to reduce carbon dioxide emissions in steel production processes. These innovative approaches highlight a shift towards more sustainable practices in the steel industry, aiming to mitigate the environmental impact of steel manufacturing.