Revolutionizing Food Production with Green Hydrogen and Microbial Proteins

Key Ideas

- The global food system's environmental impacts can be mitigated through innovative approaches like microbial protein production using green hydrogen.

- Microbial proteins offer a sustainable alternative to traditional livestock products and can help address the projected increase in food system impacts by 2050.

- Advancements in renewable energy sources and technologies like direct air capture of CO2 enable the industrial-scale production of microbial proteins based on chemoautotrophic microorganisms.

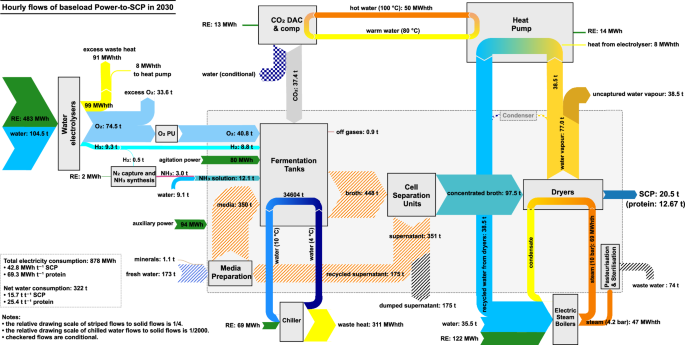

- The proposed e-SCP plant in 2030 showcases a Power-to-SCP production chain that utilizes green hydrogen for the sustainable production of single-cell protein.

The global food system is facing challenges in meeting the growing demand for food products while also reducing its environmental impacts, particularly in terms of greenhouse gas emissions. Livestock production, a significant contributor to these emissions, is not sustainable in the long run due to its environmental footprint. Scientists are advocating for a transformation of the food system to align with sustainable development goals and the Paris Agreement. One promising solution is the adoption of microbial proteins produced through chemoautotrophic microorganisms using green hydrogen as an energy source.

Microbial proteins offer a sustainable alternative to traditional livestock products and could help alleviate the increasing strain on planetary boundaries caused by food production. These proteins, derived from microorganisms like algae, yeast, fungi, and bacteria, provide a high protein content and can be produced in industrial-scale fermentation tanks. The use of renewable energy sources like solar PV and wind power, along with water electrolysis for green hydrogen production, has made the shift towards sustainable protein production feasible.

The development of an e-SCP (electric single-cell protein) plant proposed for 2030 demonstrates the potential of this approach. By utilizing H2-oxidising chemoautotrophic microorganisms for CO2 assimilation, this plant aims to produce single-cell protein in a sustainable and efficient manner. The process involves a baseload Power-to-SCP production chain that leverages green hydrogen and renewable energy sources to create a circular and environmentally friendly food production system.

Overall, the combination of microbial protein production with green hydrogen presents a promising pathway towards a more sustainable global food system. By reducing reliance on traditional livestock products and transitioning to innovative protein sources, the food industry can address the challenges of food security, environmental sustainability, and climate change.