AIMEN Achieves Milestone with 3D Printed Cryogenic Tank for Liquid Hydrogen Aviation Storage

Key Ideas

- The AIMEN technology center in Spain successfully produced the first 3D printed cryogenic tank for storing liquid hydrogen, a breakthrough for the aeronautical industry's quest for sustainability.

- The tank, part of the European OVERLEAF project, is designed to reshape aircraft architecture by incorporating clean, high-performance technologies to reduce carbon emissions.

- The innovative tank, with a diameter of 1.5 meters, features a structure made of high-performance thermoplastic for cryogenic insulation and an outer layer of carbon fiber for mechanical strength.

- The collaboration with the French technology center CANOE led to the development of a new lightweight, robust, and sustainable composite material, aligning with the goals of the European Green Pact 2050.

The AIMEN technology center in Spain has successfully developed a groundbreaking 3D printed cryogenic tank for storing liquid hydrogen, marking a significant advancement in the pursuit of sustainability within the aeronautical industry. This innovative tank, created as part of the European OVERLEAF project led by ACITURRI, aims to introduce sustainable and high-performance solutions for future aviation needs. By designing a low-pressure liquid hydrogen storage system utilizing state-of-the-art materials and manufacturing processes, the project seeks to revolutionize aircraft architecture to integrate clean technologies.

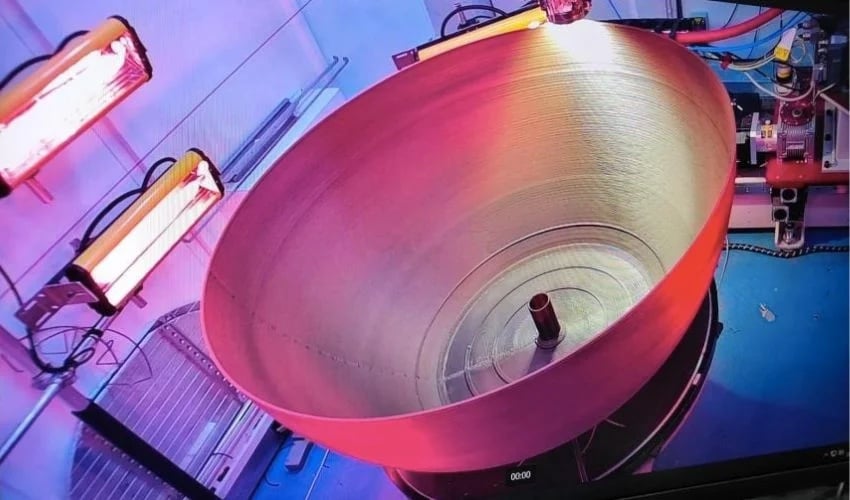

The newly manufactured cryogenic tank is a vital component for hydrogen to emerge as a viable alternative to traditional fossil fuels in aviation, given the extreme storage conditions present in this sector. The tank, with a 1.5-meter diameter, features a unique structure comprising an inner shell made of high-performance thermoplastic for cryogenic insulation and an outer layer constructed from carbon fiber to provide mechanical strength.

The production process, which lasted over 100 hours, involved advanced additive manufacturing technologies within a robotized cell equipped with a 3D printing system and infrared heating for optimal layer adhesion. Collaboration with the French technology center CANOE resulted in the development of an innovative composite material using biosourced thermoplastic and natural fibers, emphasizing lightweight, robust, and sustainable structural production.

This technological breakthrough not only showcases the potential of 3D printing and process engineering but also underlines a commitment to sustainable aviation practices aligned with the objectives of the European Green Pact 2050. The achievement signifies a crucial step towards reducing carbon emissions and enhancing the environmental footprint of the aeronautical industry.