HYScale Project: Pioneering Resource-Efficient Green Hydrogen Production in Europe

Key Ideas

- The HYScale project demonstrates efficient green hydrogen production without critical raw materials or harmful substances, advancing Europe's decarbonization goals.

- AEMWE system targets industrial-scale hydrogen production at competitive cost, achieving a CAPEX of $428 per kilowatt.

- Sustainable materials like AionFLX™ membrane and ionomer platform enable durable and cost-effective production, simplifying assembly and improving consistency.

- Collaboration with European partners is driving key innovations in catalysts, porous transport layers, and stack assembly for rapid commercialization.

The HYScale project funded by the European Union is showcasing a breakthrough in green hydrogen production by eliminating the need for critical raw materials (CRMs) and harmful substances like per- and polyfluoroalkyl substances (PFAS). By developing an anion exchange membrane water electrolysis (AEMWE) system, HYScale aims to achieve industrial-scale hydrogen production at a competitive cost of $428 per kilowatt. This initiative addresses the resource barriers faced by current green hydrogen technologies by focusing on CRM- and PFAS-free catalysts, membranes, and ionomers while ensuring efficiency and durability.

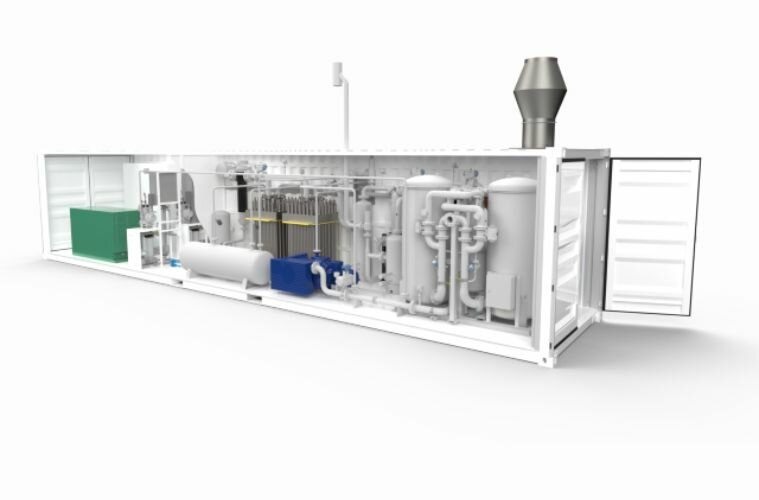

A significant milestone of the project is the successful design and testing of a 100 kW single-stack AEM electrolyzer system that operates at high current densities, nearly triple the state of the art. The project's proprietary AionFLX™ membrane and ionomer platform, developed by partner CENmat, has shown exceptional conductivity and durability in low-concentration alkaline solutions, simplifying production and enhancing consistency.

To facilitate efficient scaling, HYScale adopts a flow field-free design that reduces machining steps and enhances compactness. Economic bipolar plates and porous transport layers with reduced nickel content further contribute to affordability and sustainability. The project's collaborative approach involving partners like the Italian National Research Council, Bekaert, and DLR from Belgium and Germany focuses on refining catalyst application, membrane performance, and stack assembly.

Key innovations include high-performance, CRM-free catalysts, PTL production with reduced nickel content, advanced sealing and frame design for large-area cells, and diluted KOH operation to simplify systems and reduce corrosion risk. This project builds on previous EU-funded initiatives like NEWELY, Anione, and ECO2Fuel, consolidating research efforts for rapid commercialization of green hydrogen technology.